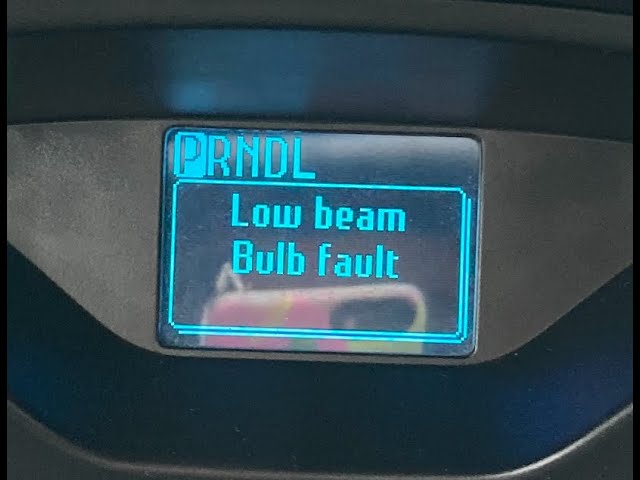

Seeing the Ford low beam bulb fault message for the first time can be unsettling; and honestly, it should grab your attention. Headlights aren’t just about convenience; they’re a core safety system, and modern Ford models continuously monitor lighting circuits to ensure the vehicle remains roadworthy and predictable in low-visibility conditions.

What often confuses drivers is the pattern: your turn signals may work normally, the daytime running light strip might still glow, and even the high beams may appear fine. Yet the moment you switch on the low beams, you may notice a brief flash, then darkness; and the dashboard throws up a warning that the low-beam system has malfunctioned.

This guide breaks down what that message really means, why it happens, and how to fix it using a methodical diagnostic approach; starting with the most common (and cheapest) solutions first. I’ll also cover the frequent “gotcha” scenario: LED conversions that don’t play nicely with Ford’s bulb monitoring strategy.

So, what causes the Ford low beam bulb fault message; and what can you do about it? Let’s work through the most likely triggers and the fixes that actually hold up in real-world troubleshooting.

What Causes the Ford Low Beam Bulb Fault Message?

Ford’s lighting control system (depending on model and year, typically managed through modules such as the BCM or an equivalent body control computer) checks for expected electrical load and circuit behavior when you activate your low beams. If the system detects something abnormal; like a circuit drawing too little current, too much current, an intermittent connection, or a failure to energize properly; it will trigger a warning.

While there are multiple causes, the most common is still the simplest: a failing or failed low-beam headlight bulb. Close behind that are connector problems (often heat-related), general wiring or control issues (fuses, relays, harness damage), and LED bulb compatibility problems that confuse the vehicle’s bulb monitoring logic.

Let’s break the common causes down clearly and practically, with repair guidance you can actually apply.

Possible Cause #1: Burned Out Bulb

Even though low-beam bulbs feel like “set-and-forget” parts, they’re consumables. Halogen low-beam bulbs have a finite service life, and in many Ford vehicles they will eventually fail due to heat cycling, vibration, and the natural deterioration of the filament. If your Ford is older and the bulbs have never been replaced, you’re essentially driving on borrowed time.

A typical automotive bulb can last around 1,000 hours, but that number is not a guarantee; it varies dramatically depending on how often you drive at night, whether you run lights in daytime conditions, and how stable your charging system voltage is. A vehicle that spends its life on rough roads, in extreme temperatures, or in stop-and-go driving (more vibration and heat soak) can shorten bulb life.

It’s also worth knowing that bulbs don’t always fail in a clean “on/off” way. Some bulbs become intermittent as the filament weakens. That intermittent behavior can lead to the exact symptom many Ford owners describe: a low beam that flickers briefly, then cuts out, followed by a warning on the dash.

How to Fix: Replace the faulty low-beam bulb (it may be one side or both). If one has failed and the other is the same age, consider replacing them as a pair for consistent brightness and color temperature.

Start by identifying the exact bulb type your Ford requires. Your owner’s manual will list it, and some vehicles also label the bulb type on the headlamp housing. Buying the correct specification matters; especially for vehicles with projector housings or specific beam patterns where mismatched bulbs can reduce visibility or create glare.

In many Ford models, the job is straightforward: you open the lamp access hatch, remove the connector, release the bulb retainer, and install the new bulb without touching the glass. In other models, access can be tight and may require removing surrounding panels, the airbox, or partial headlamp fasteners. If the layout is cramped, use the manual as your step-by-step reference or have a technician do it quickly and cleanly.

Expert note: Avoid handling halogen bulb glass with bare fingers. Oils can create hot spots, reducing bulb life. If you accidentally touch it, clean the bulb with isopropyl alcohol and let it dry before installation.

Possible Cause #2: Loose or Damaged Connectors

If your bulb is good (or you replaced it and the fault returned), the next prime suspect is the connector at the back of the headlamp assembly. Low-beam circuits generate heat, and over time that heat can fatigue terminals, soften plastic housings, and reduce contact tension. Once the connection becomes marginal, you get resistance, arcing, even more heat, and eventually an intermittent or complete failure.

This is one of the most common “why does it work sometimes?” scenarios. A connector might make contact when cool, then open up as it warms. Or it may work when you hit a bump, then fail again. Ford’s monitoring system can read that behavior as a bulb or circuit fault; because electrically, it behaves like one.

How to Fix: With the vehicle safely parked, start the engine and switch on the lights. Open the hood, locate the connector at the back of the headlight unit, and inspect carefully for looseness, discoloration, melting, corrosion, or damaged locking tabs.

As you inspect, gently move the connector and harness (don’t yank it). If the low beam flickers or cuts in/out while you move the connector, you’ve likely found your culprit.

For a more reliable inspection, remove the headlight assembly if your model allows it without too much effort. That gives you better visibility of the terminal pins and the bulb holder’s fitment. In many cases, the bulb holder connectors loosen over time or show heat damage.

If the terminals are loose, you may be able to carefully restore tension using long-nosed pliers. If the connector body is damaged, brittle, or melted, replacement is the right fix. Here’s a helpful reference on the replacement approach: replace the connectors.

Expert note: If you see greenish corrosion on terminals, clean it with a proper electrical contact cleaner and a small brush. However, if corrosion has migrated into the copper strands of the wiring (a “blackened wire” look under the insulation), the best repair is cutting back to clean copper and splicing in new wiring using proper sealed connectors.

Possible Cause #3: Other Wiring Problem

The low-beam system is bigger than the bulb and its socket. The headlamp circuit depends on the wiring harness, switching logic (often via relays or solid-state drivers), and protective devices like fuses. If any of these components fail; or if the harness is damaged; the low beams may not receive the correct power or ground, triggering the Ford low beam bulb fault message.

Although deeper wiring problems are less common than bulb or connector issues, they absolutely occur. You may see them after collision repairs, water intrusion, rodent damage, poorly installed aftermarket accessories, or years of vibration that eventually breaks a conductor internally.

Some failures are also “conditional.” For example, a relay may work when cool but fail when hot. A ground point may conduct until moisture gets involved. A wire may make contact until the engine bay shifts under torque. These issues can imitate a bulb failure but persist even after replacing parts.

How to Fix: Begin with the basics: check the low-beam fuse. The fuses are located in the fuse box (some models have more than one fuse panel), and your owner’s manual will specify the correct fuse location and rating. Replace a blown fuse with the correct amperage.

If the fuse is intact, the issue is more likely a relay/switching fault or a wiring/ground problem. Turn the lights off, remove the bulb, and inspect for signs of heat at the bulb base and connector. If your model uses an accessible relay, test it or swap it with a known-good relay of the same type (only if the manual confirms it’s interchangeable).

Use a multimeter or test light to confirm power and ground at the low-beam connector when the low beams are commanded on. If power is present but the bulb does not illuminate, suspect the connector, bulb seating, or bulb. If power is missing, work upstream: fuse, relay/driver, switch command, and harness integrity.

Detach and clean electrical contacts with a suitable electrical contact cleaner where contamination is present. Then test again. If you have access to wiring diagrams for your specific Ford model and year, use them; guesswork in electrical diagnostics is how unnecessary parts get replaced.

Note: Troubleshooting wiring faults can be frustrating if you don’t have the tools or experience. There’s no shame in booking a diagnostic visit with a qualified specialist or your dealer; especially if the fault is intermittent or involves modules that require scan-tool testing.

Possible Cause #4: Installed LED Bulbs

Aftermarket LED conversions are a very common reason Ford drivers get a low-beam bulb fault message even though the lights “should” work. The issue is rarely the LED itself; it’s the electrical behavior. LEDs typically draw far less current than halogen bulbs, and Ford’s system may interpret that low current draw as a blown filament (because that’s exactly what a burned-out halogen bulb looks like electrically).

In some cases, the LED driver circuitry also creates unusual electrical signatures (rapid pulses, voltage spikes, or inconsistent load). The result can be flicker, brief illumination followed by shutdown, warning messages, or erratic behavior when the vehicle performs bulb checks.

How to Fix: If your LED bulbs cause the fault, you have a few options depending on how deep you want to go and what your vehicle supports.

One approach is to use diagnostic tools to read and adjust configuration settings. You can buy an ELM 327 interface (a programmed microcontroller device widely used for OBD communication) and use ForScan or FoCCCus to read codes and modify certain lighting parameters. Some owners change the headlight configuration to HID and switch the low beam fault monitoring to off. In some scenarios, the warning may still appear but the low beams will operate more consistently.

Pro Tip: There may be a practical way to eliminate the error message after switching from OEM halogen to LED: install load resistors to mimic halogen current draw. Many people start with 6-ohm, 50-watt resistors, but the “right” value depends on the vehicle and bulb circuit design. Resistors also generate substantial heat, so they must be mounted safely away from plastic and wiring insulation.

Alternatively, keep things simple: use OEM-spec bulbs, or purchase a quality CANBUS wiring harness adapter. These adapters are designed to “translate” the LED load so the vehicle’s computer module interprets the circuit as functioning normally. When properly matched, a CANBUS adapter can reduce flicker, prevent false bulb-out warnings, and help protect the LED setup from incorrect current behavior.

Expert note: Beyond warning messages, also consider beam pattern and legality. Some LED retrofit bulbs in halogen housings scatter light and reduce real-world seeing distance, even if they look bright. For best results, match bulb technology to the headlamp design (reflector, projector, HID, LED module) whenever possible.

Deep-Dive Diagnostics: A Step-by-Step Troubleshooting Order That Saves Time

If you want the fastest path to a real fix (instead of swapping random parts), approach the Ford low beam bulb fault message like a technician would: start with the highest-probability failures and confirm each step before moving deeper.

Step 1: Confirm the Symptom on Both Sides

Check whether the fault is happening on the driver side, passenger side, or both. A single-side failure usually points to a bulb, connector, or localized wiring issue. A both-sides failure increases the odds of a fuse, control module issue, configuration error, or voltage/charging irregularity.

Step 2: Swap Bulbs Side to Side (When Applicable)

If both sides use the same bulb type and are accessible, swapping bulbs is an excellent diagnostic trick. If the problem follows the bulb, you’ve confirmed the bulb is at fault. If the problem stays on the same side, you’re looking at the socket, connector, harness, or control side of the circuit.

Step 3: Inspect Connector Heat Damage and Fitment

Look for browning, melting, looseness, or a burnt odor. These are strong indicators of high resistance and terminal failure. A connector that “looks fine” can still be loose; pay attention to how firmly it locks and how much movement the pins have.

Step 4: Check Fuses the Right Way

Don’t rely only on visual inspection. Use a test light or multimeter to confirm continuity and verify that power is present where expected. A fuse can look intact but fail under load due to hairline fractures or poor contact at the fuse blades.

Step 5: Verify Power and Ground at the Low-Beam Socket

This is where you stop guessing. When the low beams are turned on, you should see proper voltage at the connector and a solid ground path. If voltage is missing, trace upstream. If ground is poor, locate and clean the ground point or repair the ground wire.

Step 6: Consider LED/CANBUS Compatibility If You’ve Modified Anything

If you recently installed LEDs, treat them as suspect until proven otherwise. Even “CANBUS ready” packaging can be optimistic marketing rather than an engineering guarantee. The cleanest confirmation is reinstalling the original halogen bulbs and seeing whether the fault disappears.

Preventive Tips to Avoid Repeat Low-Beam Faults

Once you’ve fixed the fault, a few habits can reduce the chances of it returning:

Replace bulbs in pairs: This keeps brightness balanced and reduces the chance the second bulb fails shortly after the first.

Keep connectors clean and dry: Moisture intrusion accelerates corrosion. If the rear dust cap is missing or not seated correctly, fix that immediately.

Don’t “over-upgrade” wattage: Installing higher-wattage halogen bulbs than stock can overheat connectors and wiring, leading to terminal damage and recurring faults.

Choose quality LED solutions: If you insist on LED retrofits, use reputable brands, proper adapters, and confirm beam pattern performance; not just perceived brightness.

FAQs

Can Cleaning Improve Dim Low Beam Headlights on Ford?

Yes; cleaning can make a noticeable difference, and it’s one of the most overlooked “free performance upgrades” for headlights. Washing the headlight lens with warm water and car shampoo can significantly improve the amount of usable light reaching the road. Even in decent driving conditions, headlights accumulate grime, salt film, and oily residue that scatters light and creates glare.

If contamination is allowed to build, it can reduce effective visibility by up to 20 percent. And that reduction doesn’t just affect you; it also increases glare for other drivers because the beam becomes less controlled.

Expert tip: If your lenses are hazy or yellowed, cleaning alone may not be enough. A proper lens restoration (polish + UV protection) often restores the beam pattern and brightness far more than a new bulb alone.

Are the Low Beam Headlights Necessary on Ford?

Absolutely. Low-beam headlights are essential on any vehicle because they provide controlled, short-to-mid range illumination without blinding oncoming traffic. They’re the correct choice in urban traffic, rain, fog, dusk, and any situation where visibility is reduced and you need other drivers to see you clearly without being dazzled.

Using low beams properly is not just about compliance; it’s about preventing collisions. High beams can reflect off rain or fog and reduce your own visibility, while also putting other road users at risk.

Closing Words

A low-beam malfunction is not a warning you should postpone. It directly impacts your ability to see hazards early; and just as importantly, it affects how reliably other drivers can see you. The good news is that the Ford low beam bulb fault message is often caused by straightforward issues that can be corrected without major expense.

In most cases, start with the high-probability fixes: check the bulbs, then move to the connectors. Those two areas account for a large share of real-world failures. If the fault persists, work through fuses and wiring checks methodically, and consider LED/CANBUS compatibility if you’ve upgraded bulbs recently.

With the right approach and a bit of patience, you can resolve the Ford low beam bulb fault message and restore full, safe nighttime visibility. If you hit a wall; especially with intermittent wiring faults; bringing in a specialist can save time and prevent expensive misdiagnosis.