Having trouble with your Toyota’s parking assist system? Those reassuring beeps that normally guide you into tight spaces might suddenly go silent; or, just as frustrating, your dash may flash a warning like “Parking Assist Malfunction” or “PKSB Malfunction.” While this can feel like a minor convenience feature failing, it’s worth treating it seriously. Parking assist is designed to reduce low-speed impacts, protect pedestrians and property, and help you judge distance when visibility is limited. When it stops working, you’re not only losing a convenience tool; you may also be losing an extra layer of low-speed safety that many drivers have come to depend on.

In my experience, Toyota parking assist failures usually fall into a few predictable categories: sensor contamination (dirt, ice, road salt), wiring or connector faults, physical sensor damage after a minor bump, or software/calibration issues; especially on newer models. And sometimes the system is actually healthy, but it’s being intentionally disabled due to a related vehicle fault (such as another active warning) or because a setting was changed without you realizing it.

This guide breaks the problem down like a technician would: first, understand what system your Toyota is actually using (Toyota uses several parking-related systems that sound similar but behave differently). Next, identify the symptom and check the simplest causes. Then, confirm the fault with the right diagnostic approach, interpret codes correctly, and only replace parts when evidence supports it. We’ll walk you through what causes these systems to fail, how to diagnose the problem, and what steps you can take to get your parking assist working properly again.

What Is Toyota’s Parking Assist System?

Toyota’s “parking assist” is not a single device; it’s a family of interconnected driver assistance features. Depending on your model, trim level, and year, your Toyota may have one or several systems that work together when you park, reverse, or maneuver at low speed. Understanding which one you have matters because it changes the symptoms you’ll see, the modules involved, the sensors used, and the calibration requirements after repairs.

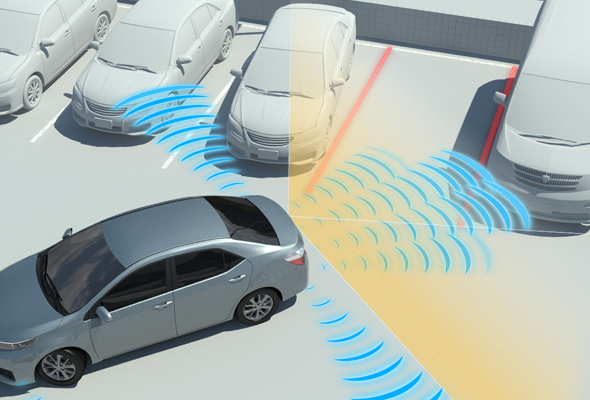

Toyota’s parking assist technology is actually a collection of interconnected systems working together to help you park safely. The main components include:

- Intelligent Parking Assist (IPA): Automatically controls steering during parking

- Parking Support Brake (PKSB): Applies brakes when obstacles are detected

- Intelligent Clearance Sonar (ICS): Uses radar and ultrasonic technology to monitor surroundings

Here’s what those systems mean in practical, real-world terms:

Intelligent Parking Assist (IPA) is the most “active” form of assistance. On equipped vehicles, it can take over steering inputs during a parking maneuver (parallel or perpendicular, depending on the generation). It doesn’t mean the car is fully autonomous; it means the vehicle can help guide the steering angle while you manage speed, gear selection, and braking based on prompts.

Parking Support Brake (PKSB) is a safety intervention feature. If the system determines you’re approaching an obstacle too quickly or that there’s a high probability of contact, it may reduce engine power and/or apply brake pressure. It’s intended to reduce low-speed collisions (e.g., bumping a wall, pole, or another vehicle) and can be especially helpful in tight garages or parking structures.

Intelligent Clearance Sonar (ICS) is Toyota’s umbrella term for sonar-based obstacle detection and warning (and, on many models, it works alongside camera-based or radar-supported systems). You’ll commonly experience it as audible beeps, visual proximity bars, and warnings that intensify as you get closer to an object.

These systems rely on 4-8 ultrasonic sensors positioned around your vehicle’s bumpers. The sensors emit sound waves and measure how long it takes for them to bounce back, calculating the distance to nearby objects with impressive precision.

Expert note about sensor behavior: Ultrasonic sensors are excellent for measuring distance to hard surfaces (walls, vehicles, poles) at low speed. However, they can struggle with irregular objects (thin chains, soft bushes), angled surfaces, or conditions that distort sound waves (heavy rain, snow buildup, thick road grime). That’s why Toyota’s newer systems increasingly blend sonar with cameras and, in some cases, radar; each sensor type compensates for the others’ weaknesses.

Where the sensors live and why that matters: These sensors sit in the front and rear bumper covers; exactly where road debris, winter salt, bumper taps, and car wash impacts are most likely to happen. They are also frequently painted to match the bumper, and the sensor’s face must remain within a specific thickness and finish standard. Heavy paint layers, thick clear coat repairs, or aftermarket bumper covers that don’t match factory geometry can all affect how reliably the sensors transmit and receive sound waves.

Why you may have “parking assist” but different symptoms than someone else: A Toyota RAV4 with rear sonar may only beep in reverse. A Highlander with 360° camera and ICS may beep in both directions and also auto-brake. A Tundra may have additional configuration logic for towing. So, the same complaint; “my parking assist isn’t working”; can mean different things depending on how the vehicle is equipped.

Common Causes of Toyota Parking Assist Malfunctions

Parking assist problems almost always trace back to one of four root causes: (1) the sensors can’t see due to contamination or environmental conditions, (2) the sensors or wiring are physically damaged, (3) the electrical network is compromised (power, ground, communication), or (4) the system requires calibration/initialization or is being suppressed due to another vehicle fault.

Let’s go through the most common failure triggers in a practical order; starting with the issues you can verify quickly without tools.

Dirty or Obstructed Sensors

The most frequent cause of parking assist problems is simple sensor contamination. Your parking sensors can’t “see” properly when they’re covered with:

- Road dirt and grime

- Snow and ice buildup

- Mud splatter

- Salt residue from winter roads

This is especially true in winter, when the sensor face can become coated with a thin layer of frozen slush that is nearly invisible. From the driver’s seat, the bumper “looks fine,” but the sensor is effectively sealed under a translucent layer that blocks or distorts the ultrasonic signal. In other climates, thick mud, clay, or heavy dust can have a similar effect.

In winter conditions, ice formation is particularly problematic. Some Toyota owners report parking assist systems remaining non-functional until their vehicles warm up in heated garages.

Professional insight: Toyota systems may disable parking assist when the sensor output becomes implausible or noisy. That’s not a “bug”; it’s a safety strategy. A sonar system that is reading garbage data could either fail to warn you or warn you constantly. In many cases, Toyota prefers to shut the feature down and alert you rather than let it behave unpredictably.

Contamination is not limited to dirt: Wax buildup, thick sealants, and certain ceramic coatings can also affect sensor performance if they are applied too heavily on the sensor face. Most detailing products are safe when applied correctly, but sensor faces should not be treated like the rest of the bumper with layers of thick product.

What “dirty sensor” malfunctions often look like:

- System works after a car wash, then fails again after a snowy/dirty drive

- Intermittent warnings that come and go with weather changes

- False beeping or constant alerting that stops after cleaning

Electrical and Wiring Problems

Electrical issues are another major culprit behind parking assist failures:

- Damaged wiring harnesses

- Corroded connections

- Broken sensor cables

- Communication circuit errors

Wiring problems often show up after: minor bumper repairs, trailer wiring installations, tow hitch additions, rear impact events, or off-road use that exposes wiring to debris. Even a small harness pinch behind a bumper cover can create intermittent opens or shorts that shut the system down.

What makes these issues tricky is that Toyota parking sensors are connected in series. This means one faulty sensor or damaged wire can disable the entire system. When your scan tool shows code C1AED, you’re likely dealing with a front sensor communication failure.

Expert explanation of “series” behavior: In many Toyota implementations, sensor signals and power distribution are arranged so that one failure can interrupt the network or the sensor chain. Think of it like old-school holiday lights: one failed bulb could take out the string. Modern systems are more robust than that analogy, but the principle still applies; one compromised circuit can cause a system-level shutdown.

Electrical faults can be intermittent: A harness that is barely broken may work until you hit a bump, until the bumper flexes in heat, or until moisture enters a connector. That’s why some parking assist failures appear random and why a quick scan at the shop may show “history codes” rather than an actively present fault.

Corrosion is more common than many owners expect: Parking sensors are mounted low and face the environment directly. Road salt and moisture can wick into connectors and cause terminal corrosion, which increases resistance and disrupts communication. This is especially common in regions with salted winter roads.

Physical Sensor Damage

Parking sensors sit in vulnerable positions on your bumpers, making them susceptible to damage from:

- Minor bumper impacts

- Road debris strikes

- Shopping cart collisions

- Car wash equipment

Even a “no visible damage” bump can shift a sensor mount, crack a sensor internally, or damage a retaining clip. A sensor can still look intact from the outside while the internal transducer has been compromised. The result can be false alerts, blind zones where the system doesn’t warn, or a complete malfunction.

Even seemingly minor damage can cause sensors to trigger false alerts or fail to detect obstacles entirely.

How physical damage often presents:

- One corner of the bumper gives constant beeps even when nothing is there

- System works until you shift into reverse, then immediately errors out

- After a minor bump or parking lot tap, the malfunction starts the next day

Sensor seating matters: If a sensor is not fully clipped into the bumper bracket, it may point at a slightly incorrect angle. Because these sensors operate on reflections, a small angle change can make the system “see” the ground too strongly or miss objects at normal height; creating unreliable warnings.

Issues with Related Vehicle Systems

Sometimes the problem isn’t with the parking assist system itself but with other vehicle systems that affect whether Toyota allows parking assist to operate. Modern vehicles often apply a “safe mode” logic: if the car has an unresolved fault in a related system, it may disable certain driver assistance features to prevent unpredictable interactions.

Sometimes the problem isn’t with the parking assist system itself but with other vehicle systems:

- Active check engine light (often disables parking assist as a safety measure)

- EVAP canister problems

- Active grille shutter malfunctions

- Even a loose fuel cap can trigger issues

Additionally, aftermarket modifications like trailer hitches, bike racks, or custom bumpers can interfere with sensor operation.

Why modifications matter: Parking sensors do not “know” what is factory and what is added later. A trailer hitch receiver, bike rack, or even certain bumper guards can sit within the sensor field and cause constant beeping or trigger fault logic. Some systems are smart enough to ignore steady objects, but many will still warn or disable because the obstacle is always present. Similarly, custom bumpers may place sensors at non-factory angles or use materials that reflect sound differently.

A note on towing and hitches: Some Toyota models have settings to adjust sensor behavior when towing, but this varies widely. If you recently added a hitch and started getting malfunctions, that timeline is important evidence.

Warning Signs of Parking Assist Problems

Parking assist problems don’t always start with a dramatic error. In many cases, the system becomes inconsistent first; missing objects occasionally or warning when nothing is there. Recognizing early warning signs can prevent a low-speed impact and can also save money because you can address a small connector issue before it becomes a major harness repair.

How do you know when your parking assist system is acting up? Look for these telltale signs:

- “Parking Assist Malfunction” warning on dashboard

- “Check Parking Assist” message

- “PKSB Malfunction” warning

- Complete absence of parking sensor beeps

- Intermittent or unreliable sensor warnings

- Continuous beeping without obstacles present

Expert interpretation of each symptom:

- Total silence/no beeps: could be system disabled, a blown fuse (rare but possible), a module communication issue, or the feature turned off in settings.

- Intermittent warnings: very often contamination, moisture, or a connector/harness issue that comes and goes.

- Constant beeping with nothing present: commonly a sensor face covered by ice or mud, a damaged sensor, or a sensor misaligned so it “sees” the ground/bumper.

- PKSB malfunction specifically: indicates the braking-support function is affected. You should be extra cautious because the system may not brake when expected.

One more easy-to-miss cause: Many Toyota vehicles allow you to disable sonar warnings or change the beep volume. If you recently had the battery disconnected, software updated, or settings changed, verify that the feature is enabled and the volume isn’t set to “low/off.” A surprising number of “it stopped beeping” complaints are actually settings-related.

Diagnosing Parking Assist Problems

Accurate diagnosis matters because Toyota parking assist components can be expensive, and replacing parts without evidence is a fast way to spend money and still have the same warning. The goal is to confirm whether the issue is (1) environmental/temporary, (2) sensor-specific, (3) harness/power/ground related, or (4) module/software/calibration related.

Start with the least invasive checks: clean the sensors, inspect the bumper area, and verify settings. If the problem persists or you have a warning message, move into code-based diagnosis.

Using Diagnostic Tools

Modern Toyota parking assist systems require specialized diagnostic equipment:

- Toyota Techstream: Toyota’s proprietary diagnostic software

- Professional-grade OBD-II scanners: Must be compatible with Toyota’s systems

Generic code readers often can’t access parking assist modules. Many low-cost OBD-II scanners can only read emissions-related powertrain codes. Parking assist faults may live in separate modules (clearance sonar ECU, PKSB module, body ECU, camera ECU). If your scanner can’t access those modules, it will incorrectly report “no codes,” even though the car is actively displaying a parking assist malfunction message.

Even when using professional tools, technicians sometimes struggle to locate parking assist modules in the diagnostic software. In some cases with 2022 models, technicians had to select 2021 model year settings to access clearance warning modules.

Expert guidance: If you’re paying for diagnosis, confirm the shop can access Toyota-specific modules. “We scanned it and found nothing” often means the scan was limited to the engine computer only. A proper diagnostic session should include a full “health check” across body and driver assistance systems.

Why Techstream is the gold standard: Techstream can access Toyota ECUs, show live data (like sensor distance values), run active tests (forcing sensors to ping), and execute calibration routines. That last part; calibration; is often the dividing line between DIY and professional repairs on 2017+ vehicles.

Common Error Codes

When diagnosing parking assist issues, you’ll likely encounter these codes:

| Error Code | Meaning |

|---|---|

| B1B44 | Rear right outer sensor failure |

| B1B46 | Rear right inner sensor failure |

| B1B48 | Rear left outer sensor failure |

| B1B50 | Rear left inner sensor failure |

| C1AED | Front sensor communication failure |

| B1B57 | Power circuit issue (front sensors) |

| B1B58 | Power circuit issue (rear sensors) |

Multiple simultaneous codes often point to a common cause, like damaged wiring harnesses or control module failures.

How professionals read these codes: A single sensor code (like B1B44) often points to that sensor or its immediate wiring. But if you get several sensor codes at once; especially all rear sensors or all front sensors; suspect a shared power/ground issue, a harness connector problem, or a module feed problem. Think of it like a string of lights: if one bulb is out, that bulb is suspect; if the whole section is out, suspect the power source.

Why “communication failure” matters: A code like C1AED suggests the system is not receiving expected data from the front sensor network. This can be caused by a failed sensor that disrupts the chain, a wiring break, a connector issue, or a module that isn’t powering the sensors correctly.

Code context matters: Codes should be paired with freeze frame data (when available) and symptom timing. If codes set only during heavy rain, moisture intrusion becomes more likely. If they set only after a bumper repair, harness routing or connector seating becomes a strong suspect.

DIY Testing Methods

If you don’t have access to professional diagnostic equipment, you can still perform meaningful basic checks; just keep expectations realistic. DIY checks can often confirm contamination or obvious damage, and they can sometimes isolate a single dead sensor. But they cannot replace calibration procedures when Toyota requires them.

If you don’t have access to professional diagnostic equipment, you can perform basic checks:

- Visual inspection: Examine sensors for visible damage or debris

- Multimeter testing: Functional sensors typically show readings above 500 ohms between terminals

- Sound test: Listen for the characteristic clicking sound sensors make when activated

- Cleaning test: Clean sensors thoroughly and test system functionality

Expert expansion: how to do each test correctly

1) Visual inspection: Clean the sensor faces first so you can see their surface. Look for cracks, chips, missing paint, pushed-in sensors, loose retaining rings, and sensors that sit at a different depth than the others. Also inspect the bumper area for signs of a prior impact (misaligned bumper cover, broken clips), because that can stress wiring and mounts.

2) Multimeter testing: If you are comfortable using a multimeter, measure resistance across sensor terminals (vehicle off). A reading above 500 ohms is a general guideline for many sensors, but values vary by design. The goal is consistency: sensors of the same type on the same bumper usually show similar readings. If one sensor reads wildly different (or open circuit), it becomes a suspect.

3) Sound/click test: Many ultrasonic sensors emit a faint clicking when active. With the vehicle in reverse (with brake applied and wheels chocked, and safely positioned), you may be able to hear or feel the sensor clicking by placing your ear close; or better, using a mechanic’s stethoscope. If one sensor is silent while the others click, that sensor or its circuit may be faulty.

4) Cleaning test: Thoroughly wash the bumper sensor area using water and mild soap, then dry. Avoid harsh solvents or aggressive scrubbing that could damage paint or sensor faces. After cleaning, test the system again. If symptoms improve immediately, contamination was likely the cause.

DIY safety note: If your testing requires the vehicle to be in reverse, do it in a safe, open area, with someone assisting, and never place yourself directly behind the vehicle. Use wheel chocks and keep your foot firmly on the brake.

How to Fix Toyota Parking Assist Malfunctions

Repair strategy depends on what you find during diagnosis. The best approach is to start with reversible, no-cost actions (cleaning, checking settings, inspecting obvious damage) and then move toward component replacement and calibration only if necessary.

Also remember: a parking assist system can fail in two ways; hard failure (system won’t operate) or degraded operation (false alarms, inconsistent detection). Fixing degraded operation often starts with cleaning and correcting sensor alignment, while hard failures often require code-based diagnosis.

Simple Fixes You Can Try First

Before heading to the dealer, try these troubleshooting steps:

- Clean your sensors thoroughly: Use water and mild soap to remove dirt and grime

- Check for ice buildup: In winter, make sure sensors aren’t frozen over

- Inspect for visible damage: Look for cracked, pushed-in, or missing sensors

- Check connections: Ensure all visible wiring is properly connected

- Cycle the system: Turn your car off completely for 2-3 minutes to reset electronics

Expert additions to make these steps more effective:

Cleaning technique matters: Rinse first to remove grit, then wash with mild soap, then rinse again. Avoid blasting sensors directly with a pressure washer nozzle at close range; high-pressure water can force moisture into seals or dislodge brackets. If you use a pressure washer, keep distance and do not aim directly at sensors.

Ice removal should be gentle: Don’t chip ice with hard tools; you can scratch the sensor face or damage the paint. Use warm water (not boiling), allow the vehicle to warm, or park in a warmer environment. If the vehicle warms up and the system resumes, ice blockage was likely the trigger.

System cycling: Turning the vehicle fully off and waiting 2–3 minutes allows some modules to power down and restart cleanly. This can sometimes clear temporary logic states, especially after a low-voltage event or temporary sensor interference. If the malfunction persists after cycling, treat it as an active fault that needs diagnosis.

Check the obvious “settings” angle: Verify that clearance sonar/PKSB/parking assist features are enabled in the vehicle settings. If the beeps are silent but the system seems “on,” check whether the beep volume is set to low or the display only mode is selected.

Aftermarket accessory check: If you have a bike rack, hitch accessory, or cargo carrier installed, remove it temporarily and re-test. Constant rear obstacles can cause persistent warnings or disable the system.

Sensor Replacement

If cleaning and basic checks don’t resolve the issue, sensor replacement might be necessary:

- Aftermarket sensors: $5-$150 per unit

- OEM Toyota sensors: $250+ per unit

- Labor costs: $171-$251 depending on accessibility

The total cost for replacing multiple sensors can quickly add up to $600-$1,000, especially if your vehicle requires bumper removal for access.

Expert cost guidance: Pricing varies widely because some models allow sensor access from the back of the bumper without full bumper removal, while others require removing trim panels, wheel liners, or the entire bumper cover. The labor cost also depends on whether calibration is required afterward. A “cheap” sensor replacement can become expensive if the calibration is overlooked and the system still won’t function.

The replacement process involves:

- Removing the damaged sensor

- Installing the new unit

- Connecting wiring harnesses

- Calibrating the system (crucial step)

Important detail about sensor matching: Toyota sensors may look identical but can have different part numbers and frequency characteristics depending on bumper position and vehicle generation. Some are painted; some require transfer of a painted bezel; some are keyed differently. Installing the wrong sensor can trigger persistent faults even though the sensor is “new.”

Aftermarket sensors; pro and con: Aftermarket units can be dramatically cheaper, but quality and compatibility vary. Some work fine; others trigger intermittent false alerts or fail early. If your Toyota requires calibration, an aftermarket sensor can complicate the process if it doesn’t report correct characteristics to the module. If you choose aftermarket, buy from a reputable supplier and confirm return policy.

Common mistake: Replacing one sensor based solely on a code without verifying harness integrity. Codes can point to a circuit, not always the component. If the harness is damaged, a new sensor won’t fix it.

The Critical Importance of Calibration

This is where many DIY repairs fail. Toyota vehicles manufactured after 2017 typically require professional calibration after sensor replacement. The calibration process involves:

- Bumper type registration

- Precise sensor angle measurement

- System initialization procedures

- Steering angle neutral point initialization

These procedures require specialized equipment and Toyota’s proprietary calibration software. Without proper calibration, you’ll often get “initialization incomplete” errors and continued system malfunctions.

Why calibration matters (expert explanation): Parking sensors are not simply “plug and play” on many newer Toyotas. The system needs to know the sensor’s reference position relative to the bumper geometry, and in some cases it must learn the bumper type and sensor orientation so distance readings remain accurate. Even a few degrees of misalignment can change how sound waves reflect, which changes distance calculations and can cause false positives or missed detections.

What calibration typically includes in practice: Toyota calibration may require the vehicle to be placed on level ground, with specific target distances and measurement conditions. The technician may use Techstream to register sensor IDs, initialize the system, and confirm proper operation in a test mode. Some procedures require measuring sensor height or verifying bumper design values. And if steering angle neutral point initialization is required (especially when IPA or braking interventions are involved), that step ensures the vehicle’s understanding of straight-ahead steering is correct; because parking assist logic often uses steering angle to interpret vehicle movement.

Why this is difficult for DIY: You can physically replace a sensor at home, but you usually cannot complete OEM-level calibration without Techstream access and the right procedure documentation. That’s why many “DIY sensor replacements” end with the same malfunction message, even though the hardware is now new.

When Professional Help Is Necessary

While basic cleaning and visual inspection are excellent DIY steps, there’s a clear point where professional diagnosis becomes the best investment. Parking assist systems are interconnected with body networks and sometimes with braking systems (PKSB). If you’re not equipped to test wiring continuity, check module communication, and perform calibrations, you can lose time and money chasing the problem.

While basic cleaning and visual inspections are DIY-friendly, seek professional help when:

- You’ve confirmed sensor damage requiring replacement

- Multiple error codes appear simultaneously

- You see wiring damage

- System issues persist after cleaning

- Your vehicle is a 2017 model or newer (requiring calibration)

Additional scenarios where a shop is strongly recommended:

- The system disables braking support (PKSB) and shows safety warnings

- You recently had bumper repair or repaint work (calibration may be mandatory)

- The system is sporadic and you suspect moisture intrusion (requires deeper connector inspection)

- Aftermarket accessories are involved and require configuration advice

What to tell the technician: Provide a clear symptom timeline. Mention when it started (after a snowstorm, after a car wash, after a bumper tap, after installing a hitch). Tell them whether the beeps are silent, constant, or intermittent. These details dramatically reduce diagnostic time because they point directly toward contamination, wiring, or calibration causes.

Preventing Future Parking Assist Problems

Parking assist systems are durable, but they are exposed to harsh conditions. Prevention is less about “babying the car” and more about reducing predictable stress: keep sensors clean, protect wiring, avoid unnecessary impacts, and avoid modifications that interfere with sensor geometry.

Regular Maintenance Tips

Keep your parking assist system working properly with these maintenance habits:

- Clean sensors regularly: Incorporate sensor cleaning into your regular car wash routine

- Winter precautions: Pay special attention to ice buildup in cold weather

- Visual inspections: Periodically check for sensor damage or looseness

- Protect from pressure washers: Avoid direct high-pressure sprays on sensors

- Maintain proper tire pressure: Changes in vehicle height can affect sensor calibration

Expert additions: Tire pressure affects ride height slightly, and significant height changes (especially from oversize tires or suspension modifications) can influence the practical detection pattern of sensors. While the system may still work, the “distance at which beeps occur” can feel different. On newer vehicles that require calibration, geometry changes can sometimes make the system more sensitive or less reliable.

Be mindful with bumper repainting: After a bumper repaint, ensure the body shop understands the vehicle has sonar sensors. Excess paint thickness or improper sensor masking can impair function. A competent shop will follow OEM repair guidance for sensor areas and may recommend calibration afterward.

Environmental Awareness

Be mindful of how you use your vehicle to protect parking sensors:

- Be cautious in extreme weather: Heavy rain, snow, and ice can affect functionality

- Consider parking location: If possible, park in garages during extreme weather

- Be careful with aftermarket modifications: Consult professionals before adding accessories near sensors

- Drive cautiously near debris: Avoid roads with excessive gravel or debris when possible

Expert note: Water droplets and heavy rain can create “noise” in ultrasonic sensing because the wave reflections become less predictable. The system may still work but can be less confident. If you notice false alerts only during storms, it may not be a failure; just environmental limitation.

Winter-specific tip: If your Toyota is parked outdoors in freezing conditions and you repeatedly get malfunctions, consider carefully clearing slush from sensor faces before driving. Many owners find this prevents repeated warnings that only clear after the vehicle warms up.

Toyota Models Most Affected by Parking Assist Issues

While any Toyota equipped with sonar-based parking assist can experience malfunctions, real-world reports tend to cluster around newer models with more integrated systems. More sensors and more features mean more points of failure; and more calibration needs after repair.

While all Toyota models with parking assist can experience malfunctions, these vehicles have reported more frequent issues:

- Toyota RAV4 (2019-present)

- Toyota Highlander (2020-present)

- Toyota Tundra (2022-present)

- Toyota Camry (2018-present)

- Lexus RX models (2016-present)

Why these models show up often: They are high-volume vehicles, frequently equipped with multiple driver assistance packages, and commonly driven in a wide variety of climates. For example, the Tundra is often used in harsh winter or work environments where salt, mud, and debris are more common; exactly the conditions that stress sensor systems.

Lexus note: Lexus systems are Toyota systems at their core but may include additional integration and more calibration steps depending on package level. Owners sometimes notice the system is more “sensitive” due to different tuning and more comprehensive warning logic.

Parking Assist Technology Evolution

Parking assist has evolved quickly over the past decade. Understanding the generation helps you predict how repairs work. Earlier systems were simpler: sensors and a basic control module. Newer systems are integrated with cameras, brake intervention logic, and sometimes steering assistance.

Toyota’s parking assistance technology continues to evolve:

- Early systems (pre-2015): Basic proximity warnings with limited coverage

- Mid-generation (2015-2020): Added automatic braking and steering assist

- Current generation (2021+): Integration with 360° cameras and autonomous features

The newer the system, the more complex the diagnosis and repair process typically becomes.

Expert perspective: The biggest shift is that newer systems treat parking assist as part of a broader “driver support” ecosystem. That’s why you may see parking assist disabled when another system has a fault. It’s also why calibration is now a standard part of repair; because the car is merging data from multiple sensors and must trust the geometry.

Is It Safe to Drive with Parking Assist Malfunction?

You can drive with a malfunctioning parking assist system, but you should recalibrate your habits accordingly. Parking assist is a low-speed support tool; the vehicle remains drivable without it. However, many drivers park daily in tight spaces, and losing the system increases the chance of low-speed contact.

You can drive with a malfunctioning parking assist system, but:

- You’ll need to rely entirely on your own parking skills

- There’s increased risk of minor bumper damage when parking

- The malfunction won’t affect core driving functions like steering or braking

- Some related safety systems might be disabled as a precaution

For safety, have the system repaired promptly, especially if you regularly park in tight spaces or rely heavily on parking assistance.

Expert caution about PKSB: If your Toyota specifically reports a PKSB malfunction, you should assume automatic low-speed braking assistance may not operate. That doesn’t remove your normal braking capability, but it removes a safety net. Be especially careful in garages, near walls, and around pedestrians while the system is offline.

Also consider resale and inspections: Persistent warning messages can affect resale value and may complicate warranty discussions if ignored. If your vehicle is under warranty, documenting the issue early is smart; especially if it’s intermittent and difficult to replicate later.

A Technician’s Quick Diagnostic Flow (So You Don’t Waste Money)

If you want a simple “decision tree” that mirrors a professional approach, use this:

- Is the system enabled? Check settings and beep volume.

- Are the sensors clean? Wash the bumper areas and remove ice/mud.

- Does the issue correlate with weather? If yes, contamination/moisture is likely.

- Is there visible bumper damage? If yes, suspect sensor seating or wiring strain.

- Scan with a Toyota-capable tool. Confirm which sensor/circuit is flagged.

- If one sensor is flagged, test/replace and then calibrate if required.

- If multiple sensors are flagged, check shared power/ground and harness connectors first.

- If calibration is required (often 2017+), plan for professional service.

Why this flow works: It prevents the most common mistake: replacing an expensive sensor when the real problem is dirt, ice, or a shared power feed. It also prevents the second most common mistake: replacing the sensor but skipping calibration, then assuming the new sensor is “bad.”

Final Thoughts

Toyota’s parking assist systems are sophisticated technologies that genuinely improve everyday safety and convenience; especially in tight urban parking, crowded shopping centers, and low-visibility situations. But like any sensor-driven system that lives on the bumper, it depends on clean sensor faces, intact wiring, correct sensor positioning, and (on newer models) accurate calibration. When one part is compromised, the vehicle often disables the entire feature to avoid misleading you.

Start with what you can control: clean sensors, remove ice and grime, verify settings, and inspect for obvious damage. If the issue persists, don’t guess; scan the appropriate modules with Toyota-capable diagnostic equipment. And remember: for many 2017+ Toyotas, calibration isn’t optional after sensor replacement; it’s the step that makes the repair “real.” If you’re facing persistent malfunctions, multiple codes, wiring damage, or initialization errors, professional diagnosis and calibration are often the fastest path back to a fully working system. Don’t hesitate to consult a qualified Toyota technician when needed.